| Feature | Description | Physical Components/System |

|---|---|---|

| Fast Cooling (up to Super Fast Cooling (up to 90%) 75%) | Water circulation through cooling pipes cools chamber | Coiled pipe around the chamber for cooling |

| Super Fast Cooling (up to 90%) | Water circulation through cooling coils and air ventilation with fan rapidly cools chamber | Coiled pipe around the chamber for cooling and fan for accelerated cooling |

| Efficient Air Romoval - Efficient Moisture Removal | Efficient air and moisture removal by vacuum pump | Vacuum pump |

| Efficient Heating | Efficient heating by steam from steam generator | Steam generator |

| Active Drying of the Load | Uses heating plate and vacuum pump to dry the load quickly | Heating plate and vacuum pump |

| Complete Drying of the Load | Steam from generator in combination with vacuum for complete drying | Vacuum pump and steam generator |

| Biohazard and Waste System | Biohazard filtration of air removed from chamber before sterilization. Also used for waste sterilization | Biohazard system |

Fast Cooling

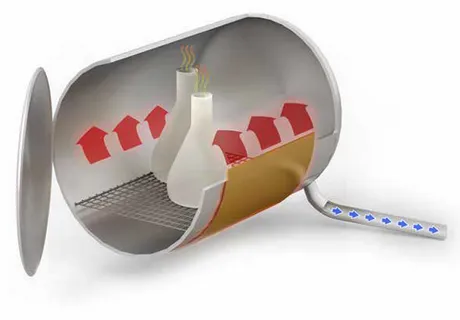

Fast Cooling is an important feature for reducing cooling time, up to 75% less time than cooling under ambient conditions. At the completion of the sterilization phase of the cycle, the chamber pressure is increased by pushing compressed air through a microbiological filter into the chamber. By increasing the pressure inside the chamber, we are able to prevent the boil-over effect for liquids, as well as spills and cracks in containers that may occur under low-pressure conditions. At this point, cold water circulates through the chamber pipes, which are coiled around the chamber and function similar to a jacket. Due to the circulation of cold water, as well as the pressurized air, the liquid load is cooled quickly and safely — thus saving you precious time and resources.

Super Fast Cooling

Used in conjunction with Fast Cooling, another way of cooling a liquid load is Super Fast Cooling, which essentially uses a fan to accelerate the cooling process. By circulating the air faster inside the chamber, the fan is able to transfer the heat from the load to the cold chamber walls, thus cooling the load by as much as 90% faster.

Efficient Air Removal & Moisture Removal

The most efficient way to remove air and moisture (for non-liquid loads) is with a vacuum pump. The vacuum pump uses an advanced system of fractionated pre-vacuum air removal pulses in order to remove more than 99% of the air inside the chamber. This process removes air pockets in the load, which is especially important in hard-to-access places like inside the bottom of a very tall beaker.

More than just removing air efficiently, the vacuum pump also contributes significantly to drying the chamber and load quicker than other methods. During the drying phase, the vacuum pump keeps pressure low, and this low pressure state reduces the boiling temperature and forces the hot moisture to evaporate quickly inside the chamber. In other words, the vacuum squeezes out the vapor (moisture) and the chamber is left completely dry.

Efficient Heating

The steam generator pumps steam into the coiled pipe around the chamber, and this is what causes the autoclave to heat up quickly. This also provides uniform heat throughout the whole chamber and prevents any cold spots. This is a faster and more efficient method than using a regular electric heating plate on the outer chamber wall surface.

Active Drying & Complete Drying of the Load

It used to be that the way to dry the load at the end of a cycle was to open the door and let the load dry slowly under ambient (room-temperature) conditions. Open-Door Drying, thankfully, has been replaced by Active Drying and the more advanced, Complete Drying.

Active Drying uses a heating plate and vacuum pump in order to dry the load much quicker than open-door drying. The heating plate heats up the chamber, thus speeding up drying of the load. And the vacuum pump lowers the pressure, thus reducing the boiling point, and resulting in high-speed evaporation. The combination of heating and vacuum guarantees that even difficult-to-dry loads such as textiles, hollow instruments and porous loads are completely dried.

The most advanced method available to dry your load quickly and efficiently is Complete Drying. With Complete Drying, the autoclave uses a vacuum pump (as described in the previous paragraph), as well as a steam generator, which heats up the walls of the chamber by sending steam into a coiled pipe around the chamber, thus heating it up rapidly and completely. The combination of lowering the pressure via the vacuum pump and rapid heating of the chamber equals fast and dependable drying of your load.

Biohazard & Waste System

Since many laboratories deal with biohazard media that can be dangerous both to staff handling the media, as well as the lab environment, it is crucial to have an appropriate sterilization solution in dealing with said biohazard media. The Biohazard & Waste System feature allows for just that.

During the air removal (from closed chamber with load inside) and heat-up stage, the chamber air is passed through a microbiological filter and leaves the autoclave as sterile air. In the sterilization stage, there is no exhaust, thus allowing no opportunity for dangerous fumes to escape. The load is sterilized, as is the air filter. And finally, by cycle end, the load, effluent, and air filter are all completely sterile.

Features for Safety and Productivity

In this guide we have presented you with a quick-reference table of our most common laboratory autoclave features, and then explained each one in more detail.

First we explored Fast Cooling and Super Fast Cooling and discussed how water circulation through cooling pipes cools the chamber, and how the optional fan feature rapidly cools down the liquid load.

Next we looked at Efficient Air Removal and Efficient Moisture Removal and understood how the vacuum pump efficiently removes air and moisture inside the chamber.

Then we explored Efficient Heating in which we discussed the advantage of using a steam generator to distribute steam into a coiled pipe surrounding the chamber, thus heating up the autoclave efficiently and quickly.

In Drying, we focused on the differences between Open-Door Drying, Active Drying, and Complete Drying. We mentioned that Complete Drying is the most advanced option and will dry your load the quickest through its combination of rapid chamber heating by steam from the generator and the vacuum pump.

And finally we explored the Biohazard and Waste System feature in which air is safely removed from the chamber before sterilization and is sterilized when passed through a microbiological filter. At cycle end, the air, effluent, and filter are all sterile, thus maintaining safety conditions for laboratory staff and the environment.

We hope this pragmatic discussion of laboratory autoclave features was helpful and informative for you, and look forward to reading your questions and comments below.

Stay tuned for our next post in this series in which we will explore topics in biosafety.