Air filters are common in germ-susceptible locations such as labs and hospitals and even in industrial buildings and airplanes where all the air gets filtered, keeping the environment safe. Just imagine what can happen if there’s a sick person on a plane and the air is not filtered.

In this article we will discuss how air filtration is used in lab steam sterilization. In this case filtration is used as a way to protect the lab environment and lab staff from contamination. However it is relevant to the discussion of sterilization methods since it is used to reduce the bioburden level. In this post you’ll learn about air filtration and

- how steam sterilization can affect the laboratory environment,

- how the environment can potentially affect the sterile load.

- and how filtration solves these two problems.

HEPA Filter Pore Sizes

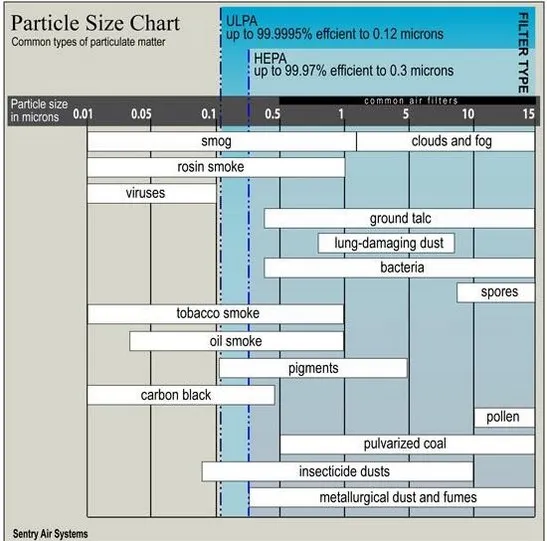

HEPA filters are designed to target tiny pollutants and particles as small as viruses that can be 10X smaller than standard bacteria. The particles are trapped through a combination of mechanisms called interception, impaction and diffusion. A detailed discussion of how each mechanism works is beyond the scope of this article. The following table specifies the sizes of the different microorganisms and particles.

HEPA filtration:

Sterilization Can Affect the Environment

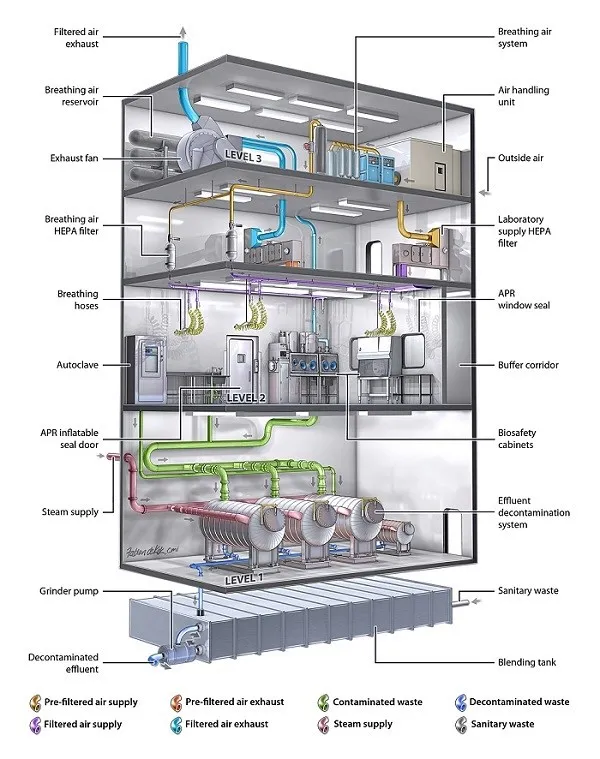

In biosafety laboratories with high risk of pathogen exposure, namely BSL3 and BSL4, the separation of hazardous materials from public spaces is vital for the protection of the lab environment and this is why the control of airflow in the lab is so important. How is this accomplished? By the use of air filters, which protect the lab environment and control airflow in and out of separate pressure zones. HEPA stands for 'high-efficiency particulate air' filters, and they are probably the most commonly used type of air filters. How do they work in BSL labs?

Air Filtration in Steam Sterilization

Filters have two intended uses in autoclaves:

- protecting the environment from potentially dangerous gasses released from the autoclave

- protecting the sterilized load from potential external contamination

Why Filter Air-Outlet When Using an Autoclave?

Air needs to be filtered when sterilizing lab instruments and biohazardous materials at pre-vacuum stage because it may contain infectious substances. For example, the air inside the autoclave chamber may include medical waste, which can be contaminated by viruses or toxins. If biohazard is released, there is a chance it will harm the drainage and ambient air, as well as laboratory staff

The HEPA air filter blocks all microorganisms from exiting the chamber during the air removal phase. The filter is so small that it blocks viruses that are an average 10X smaller than standard bacteria. This blockage, therefore, prevents the contaminated air from escaping into the atmosphere and instead, catches the harmful microorganism inside exhausting germ free air.

How Does it Work?

An autoclave sterilization cycle begins with air removal by vacuum. The air removed from the autoclave chamber for optimal steam penetration is released into the lab environment. So, before the chamber content is sterilized we already start sucking air out of the chamber by creating this vacuum. But there’s a catch, the air exiting the chamber potentially has a high level of contamination, endangering the environment. The biohazard filter which is located on the biohazard outlet line blocks these dangerous microorganisms from exiting the autoclave chamber together with the air thus keeping the lab safe.

Who Is Afraid of Water?

HEPA filters are hydrophobic. Hydrophobic filters do not pass water, and this is why they are called Hydrophobic: In Greek Hydra is water and Phobic is fear. Hydrophobic filters are designed to filter out gas for venting. A hydrophobic filter must remain dry. If it gets wet it will become blocked, and air will not be able to pass to or from the chamber. On a side note, since the HEPA filter is hydrophobic, the biohazard outlet is located in the upper-middle part of the autoclave chamber. This is to ensure that the outlet will remain condensation free and water will not block the passage of air.

The air outlet is contaminated since sterilization has not taken place yet. Filters guarantee that the air removed from the autoclave is free of harmful microorganisms. The sterilization of air by HEPA filters at pre-vacuum stage is also called green sterilization, as its main purpose is not to sterilize the media but to keep the environment safe, by leaving all bacteria and viruses inside the chamber. Once the sterilization cycle runs in the autoclave those microorganisms will be killed.

Extra Safety Meassures

We’re not done with simply blocking the bacteria with a HEPA filter. After potentially contaminated air has passed through the filter we are left with a contaminated HEPA filter packed with microorganisms. The filter also needs to be sterilized in order to make it free of living microorganisms. Some users sterilize the filter as a part of the biohazard sterilization cycle. In other cases, there is a specific program dedicated to sterilize the filter post sterilization cycle. In some BSL4 labs two filters are placed serially for extra safety: in case one of the filters fails, the second filter is there to prevent any microorganisms from passing.

Trojan Horses in the Lab

We all know the story of the Trojan horse the Greeks used to enter the city of Troy and win the war. The Greeks built a huge wooden horse and hid their soldiers in it. The Trojans pulled the horse into their city and the Greek soldiers came out of the horse at night, easily destroying the city of Troy. HEPA filter's purpose is to prevent these Trojan horses from entering the autoclave chamber.

Filters are used in autoclaves designed for BSL3 and BSL4 labs when air enters the autoclave chamber at post sterilization drying phase. It’s important that only sterile air enters the chamber after the media has already been sterilized. If we were concerned about the protection of the environment at pre-vacuum stage while sterilizing biohazard, now our main concern is to protect the integrity of the load. At the end of sterilization phase, the load in the chamber is sterile. This is why the air has to be filtered before entering the chamber to avoid the passage of microorganism which the ambient air contains. This time a HEPA filter is used in the air inlet line. At the end of the drying stage vacuum is broken inside the chamber and this is when the inlet air-line comes into action.

An Autoclave Within an Autoclave

The air filter may become contaminated. Therefore the filter needs to be sterilized to kill the microorganisms that were blocked by the filter. This is why the filter is placed in a special housing. The housing functions just like a miniature autoclave: it is equipped with a temperature sensor, steam trap for housing chamber and jacket and it sterilizes the filter thus leaving it free of living microorganism ready for the next cycle.

Tuttnauer provides an option to test filters by a WIT (Water Intrusion Test) in order to confirm that the filters are not ruptured. In addition, Tuttnauer autoclave HEPA filters use filter housing that are equipped with ports for in situ (onsite) integrity testing.

Conclusion/Summary

To summarize we just explained how air filtration is used when sterilizing biohazard or in BSL3 and BSL4 labs at pre-vacuum stage to protect the environment and at post vacuum stage to protect the integrity of the load. You are invited to share your questions and comments about HEPA filters and air filtration in lab steam sterilization in the comments section below.