AUTOCLAVES FOR FOOD & BEVERAGE

In order to eliminate any microorganisms contained not only in the food itself but also in the packaging during formation and transportation through the production machinery proper sterilization procedures need to occur. In the food and beverage industry there are three main needs for sterilization which include the need to sterilize during the food production process, the need to sterilize in a laboratory, and the actual inspection of the food item itself in a laboratory setting.

Food and Beverage Laboratories

To achieve the optimal level of sterilization in a food and beverage laboratory there needs to be correct equilibrium when dealing with specific materials, in which case your steam autoclave must deliver on some important features to succeed:

Liquid Load Fast Cooling & Super Fast Cooling

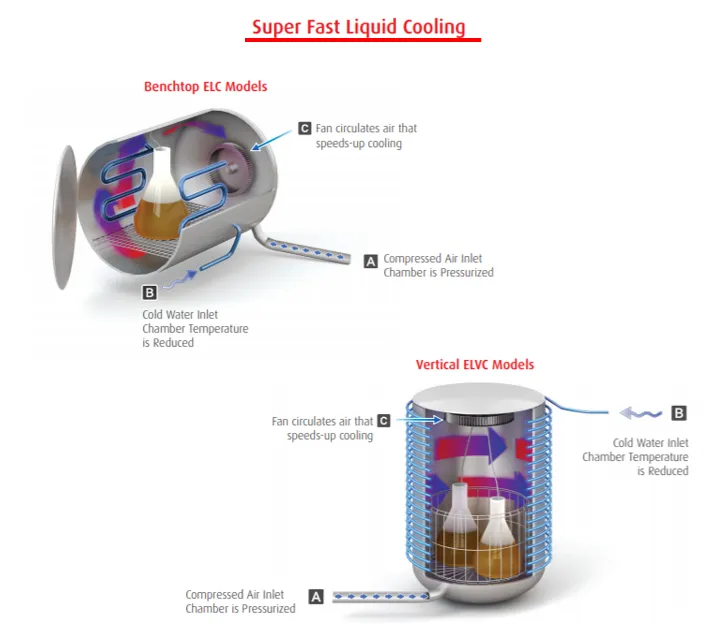

Sterilizing liquid requires longer heating and cooling times for completing a cycle, especially with sensitive liquid loads. When time is critical, advanced optional fast cooling features are important to prevent a sudden drop in chamber pressure which can cause liquids to boil over.

In addition to fast cooling, an optional fan can be applied to further circulate the compressed air in the chamber. This speeds up the heat exchange during the cooling stage in order to safely achieve super fast cooling of the liquid load under pressure. Tuttnauer’s accelerated fast liquid cooling technology reduces cycle time by as much as 90% and minimizes load exposure to high temperatures.

F0 – Protect Your Media

An additional challenge with sterilization is the need to prevent extended exposure of liquid media to high temperatures which may harm the quality of the media. The advanced F0 optional feature assists in minimizing the time the media are exposed to high temperatures during sterilization thereby protecting it. For example, a cake batter which is inserted in the oven while the temperature is ramping up to the appropriate baking time, will begin to bake as soon its placed inside the oven. This will affect the overall baking duration required and the result of potential over or under cooking the cake.

Isothermal Processing

Isothermal Processing is another application that laboratory autoclaves are designed to handle. This feature is most often used in the preparation of agar and other biological media in order to prevent coagulation and crystallization during agar preparation. The temperature settings for this cycle range from 60°C to 95°C and allow for the gentle heating and cooling down of liquid loads, like agar. Agar is a delicate medium that can be easily overcooked/caramelized if proper precautions are not taken.

Packaging – hollow & pre-vacuum air and moisture removal

The most efficient way to remove air and moisture (for non-liquid loads) is with a vacuum pump. The vacuum pump uses an advanced system of fractionated pre-vacuum air removal pulses in order to remove more than 99% of the air inside the chamber. This process removes air pockets in the load, which is especially important in hard-to-access places like inside the bottom of a very tall beaker.

More than just removing air efficiently, the vacuum pump also contributes significantly to drying the chamber and load quicker than other methods. The vacuum extracts out the vapor (moisture) and the chamber is left completely dry.