A ‘wet pack’ has moisture on or in the pack when removed from the autoclave and is a relatively common problem. Moisture may be evident as visible dampness, droplets, or puddled water on or within a pack. If more than one pack is wet, the load is regarded as a ‘wet load.’ Wet packs are subject to ‘wicking’ – they allow microorganisms to enter through the packaging, resulting in recontamination of sterile instruments. Wet packs can also cause instrument corrosion. It is essential that wet packs be identified and completely reprocessed. Read on to learn more about many causes and solutions to the problem of wet packs.

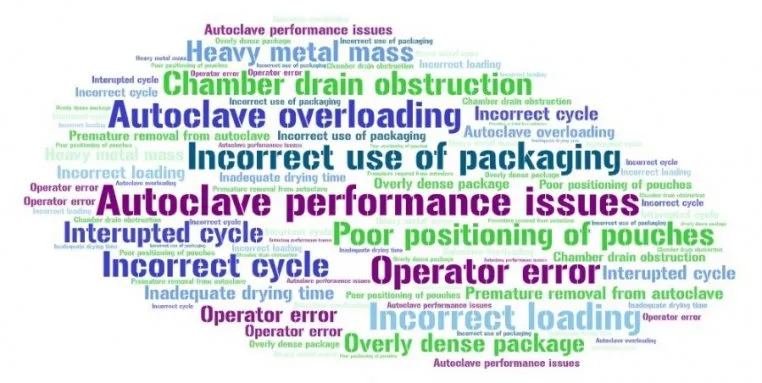

What causes wet packs?

For table-top autoclaves, there are two primary causes of wet packs – operator error and issues with the autoclave itself. While it is perhaps human nature to believe that failures are usually related to the autoclave, there are numerous operator errors that result in wet packs. Environmental conditions, such as high humidity or low temperature in cooling areas, can also result in wet packs.

Operator errors

Operator errors that result in moisture on packaging include failure to dry instruments prior to placing them in packaging, sterilization packaging errors, load and cycle errors.

- Sterilization packaging errors include placing wrap that is too tight or too loose, using incorrect sterilization packaging, double-wrapping or double-pouching packs either using sterilization packaging intended for this purpose incorrectly or using wrap or pouches not indicated for this purpose.

- Load errors include packages that are inappropriately stacked, overloading/incorrect loading of the autoclave, and packages that are too dense. Placing packs in a manner that impedes the elimination of air, paper-plastic pouches in a position that does not facilitate drying, and instruments in a position that does not facilitate drainage of moisture (e.g., concave instruments and those containing lumens such as handpieces) and/or traps moisture are all causes of wet packs. Inadvertently obstructing the chamber drain also results in wet packs. A package that is too dense, with an uneven distribution of metal mass, or one that has a heavy metal mass, is a further reason for the occurrence of wet packs. This, however, is less likely to be a source of wet packs in dentistry than many other disciplines simply because heavier instruments with greater metal mass are more frequently utilized in other disciplines.

- Cycle errors include selecting the wrong autoclave cycle. interrupting the drying cycle or selecting a drying time that is not in accordance with the manufacturer’s written instructions for use (IFU) and is inadequate. In addition, removing packs from the autoclave before the recommended cool-down period has elapsed can cause condensation to form on the package. Packs removed from the autoclave after completion of the cool-down period should not be placed on cool/solid surfaces as this can also result in condensation on the pack.

Autoclave performance issues

External and internal moisture can occur as a result of a number of autoclave performance issues. These include malfunctioning of a steam line trap, drain check valve, clogged strainers and screens, poorly calibrated pressure gauges, malfunctioning vacuum systems or other sterilizer components, and a damaged gasket (door seal). Many of these issues can be related to inadequate/lack of sterilizer maintenance which is ultimately also an operator and facility error. If indicators/print-outs show that sterilization parameters were not met, or the drying cycle was curtailed/aborted, the load must be reprocessed. It is worth noting that gravity displacement autoclaves are less effective in drying instruments than dynamic-air removal autoclaves. A systematic approach to identifying errors and issues is necessary should wet packs occur. For wet packs with internal moisture, this will only be visible once a pack is opened – it is prudent to consider reprocessing all other packs from that load, identified using the sterilization logs (in particular if a second pack from the load contains internal moisture).

Avoiding wet packs

Guidelines/recommendations and regulations related to instrument reprocessing must be followed by in each facility. Devices used for reprocessing must be indicated for the intended purpose, validated and tested in accordance with local regulations for compliance with requirements. In addition, autoclave accessories are available that position paper-plastic pouches and wrapped containers at pre-arranged distances and positions, helping to avoid overloading and incorrect loading.

The manufacturers’ IFUs for the sterilization packaging, sterilizer and the instruments/devices being sterilized must be followed. These also all help to ensure appropriate materials and processes are used and followed before, during and after sterilization. Autoclave performance issues can be adverted by following the manufacturer’s IFU and the requirements for periodic testing, maintenance and validation. If performance issues nonetheless occur, the device manufacturer’s service department should be contacted. Operator error may be a one-off error; it could also be associated with insufficient training for instrument reprocessing personnel in general or one individual. This stresses the need for proper training of personnel. If wet packs only occur at certain times of day or the year, this suggests humidity or temperature may play a role and need to be corrected.

Conclusions

Wet packs are a common problem that can and should be avoided. If wet packs do occur, the packs must be completely reprocessed. In addition, the cause of wet packs must be determined, and corrective action taken. Successful sterilization relies on repeatable, standardized steps before, during and after sterilization guided by recommendations, IFUs and regulations.

Fiona M. Collins BDS, MBA, MA

Sources:

Association for the Advancement of Medical Instrumentation. ANSI/AAMI ST79: 2017. Comprehensive guide to steam sterilization and sterility assurance in health care facilities.

Centers for Disease Control and Prevention. Sterilizing Practices. Guideline for Disinfection and Sterilization in Healthcare Facilities (2008). https://www.cdc.gov/infectioncontrol/guidelines/disinfection/sterilization/sterilizing-practices.html.

Scottish Dental Clinical Effectiveness Programme. Sterilization of Dental Instruments Dental Clinical Guidance (reviewed 2016).