You may have purchased the best cleaning products, but manual washing has been proven to have many disadvantages. So, have you considered investing in a Washer Disinfector unit?

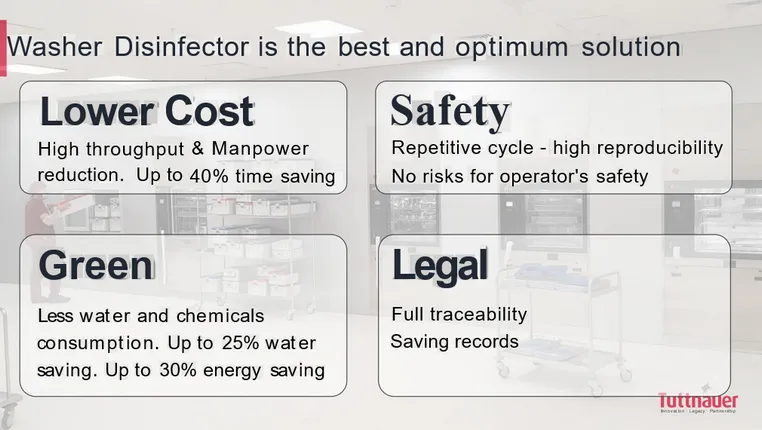

These devices are not only the best method of ensuring complete sterilization within your infection control procedures, but also saves time, manpower, water, chemicals and improves safety dramatically, ensuring complete sterilization within your infection control procedures.

The ultimate protection

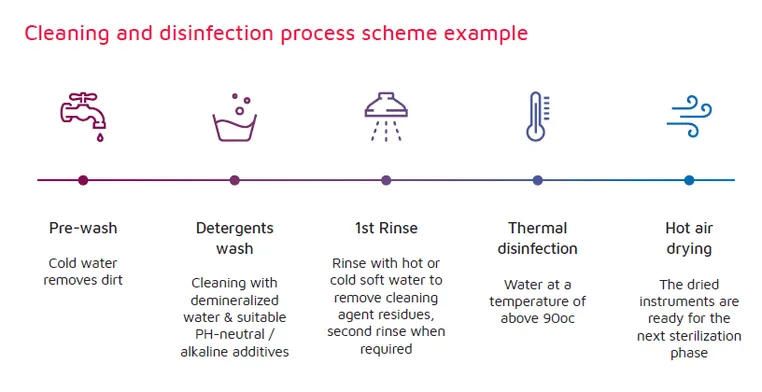

Of course, one of the biggest benefits of Washer Disinfectors is that they provide an exceptional standard of cleaning and disinfection for your instruments. After treatment, it’s essential that reusable instruments are cleaned properly, but doing this by hand leaves margin for error. With a Washer Disinfector you can guarantee that all your contaminated instruments are being effectively cleaned and disinfected to a validated standard, safe to be inspected and sterilized in your autoclave.

Furthermore, as Washer Disinfectors use specific detergents, this process can also help to preserve instruments and guard them from erosion that hand washing can cause over time. The Tuttnauer T-Clean detergent series is specifically designed for the TIVA washer product line. The T-Clean detergent line for medical instruments delivers all the ingredients that are necessary for the highest quality cleaning outcomes. This eliminates the need for any additional cleaning or conditioning products. Furthermore, The T-Clean detergent line for surgical instruments replaces costly pre-wash soaking cleaners, enzymatic cleaners, washing detergents, lubricants, and stain removers.

There are a large variety of Washer Disinfector sizes depending on your practical needs. For Example, the Tuttnauer TIVA line carries machines from 65L all the way to 430L volume. Whether you need something small to sit on a countertop or a large machine for a heavy load of washing, there is a device to meet your requirements.

Your safety is most important

Hand washing instruments comes with a number of potential risks. Not only does cleaning instruments in this way leave people open to potential of exposing staff to injury from sharp objects, but the risk of infections being passed on to people during this process is much higher in comparison to using a Washer Disinfector. If someone suffers a sharps injury, there is a chance that any infectious diseases that the patient was carrying could be transmitted.

The gold standard for cleaning and disinfection may seem cumbersome but it is the best way to ensure your decontaminating all your utensils.

Save time

In any medical practice, time is of a premium. In a busy work environment this means that hand washing instruments is unlikely to be the most efficient way forward.

Washer Disinfector units often have cycles which are short in time and can hold a vast number of instruments, streamlining the process so that the time spent hand washing can be put to better use. Furthermore, the majority of Washer Disinfectors have drying cycles, meaning that instruments are ready to be inspected and transferred to your autoclave straight away.

Keep record, keep protected

Another benefit of Washer Disinfectors is that they have features enabling you to obtain traceability of all your cycles. This ensures you keep a validated record for whenever you may need to view or revisit them.

These records are usually automatically stored and are a stress-free way of making sure you are keeping on top of your infection control procedures.

Things to consider

You are looking for powerful, reliable and customizable and at the end of the day an improved user experience. It's about making the disinfection process seamless but maintain the safety and effectiveness.

The TIVA washer disinfectors provide a flexible turnkey solution for washing, disinfecting and drying diverse medical instruments for a complete decontamination cycle. Depending on your specific needs the washer disinfector the TIVA line will minimize consumption and operation costs while maximizing sustainability in for your practical needs.

An investment that will pay off

The use of instrument washers or washer/disinfectors is another critical element in an efficient process. Instruments must be free of debris that inhibits the sterilization process. Washers clean, disinfect, rinse and dry instruments saving valuable time and avoiding the potential for percutaneous injury. Instruments must be thoroughly cleaned and dried prior to preparation and packaging for sterilization.

Instrument washers eliminate several steps of manual labor creating a more efficient and safer process. The CDC recommends automated methods for cleaning. A good quality washer can easily handle the needs of a 4-6 operatory office. Investing in this technology can be initially expensive, but over time the return on investment in labor savings is huge. Use of cassettes along with instrument washers can save up to 10 hours of labor per week which equates to 40 hours per month in labor savings which is efficient and significantly cost effective.

In summary there are many benefits to investing in a good quality Washer Disinfector. Although manual washing maybe the method of current choice, times have changed and the need to ensure ultimate safety while saving you time, cost and labor and the best user experience is what counts the most to you.