In today’s world of connectivity laboratories that have embraced new technology have ushered in the idea of a 'Smart Laboratory'. What the Smart Laboratory does is integrate various lab systems, instruments, and devices into a unified, intelligent ecosystem that improves efficiency, accuracy, and safety. From real-time monitoring to interconnected devices and advanced sterilization techniques, IoT is powering the transformation towards smart laboratories.

Technological progression and scientific advancement have always gone hand in hand! Currently, scientists face the daily task of manually recording data output from the machines, a repetitive method that is not only time-consuming but also carries a risk of human error as all humans make mistakes from time to time. Other issues that often arise are related to data loss, which can happen when a scientist has much to record and monitor. Let’s not even mention deciphering handwritten documentation.

Today the advanced laboratories are moving towards an IoT enabled laboratory that will see all devices connected to the cloud or local server, that can be controlled by the researcher externally and accessed from anywhere with an internet connection. With a number of devices and sensors connected to a central system, scientists will be able to conduct their research in a more productive manner, without unnecessary obstructions or error-related complications, saving the scientist valuable time and effort along.

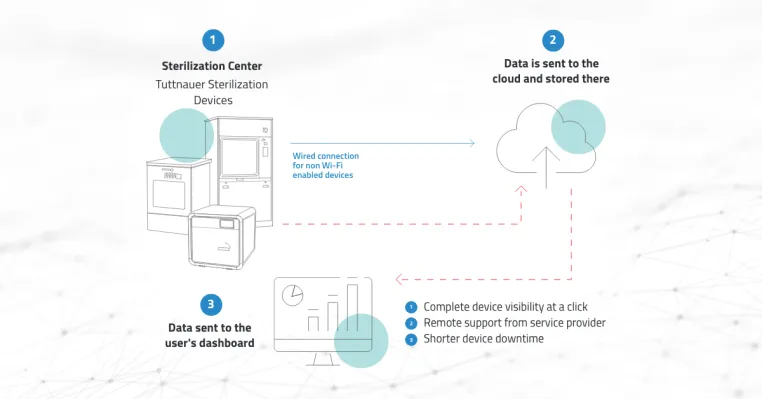

Tuttnauer has been developing sterilization devices since 1925, a true market leader in the laboratory sector for infection control devices and has been on the cutting edge of advancement in the IoT space, with the development of the T-Connect software. We have developed autoclaves for laboratories that use Wi-Fi to connect multiple devices in your sterilization center and essentially have them communicate to one central location, either on-site or remotely. The advanced T-Connect system is a cloud based IoT solution for your laboratory sterilization center. It is based on a unique device connectivity, providing labs with data intelligence in real time, accessible from anywhere, anytime, in a secure way.

The underlying benefits that IoT has enabled with Smart Laboratories include:

Real-Time Monitoring

One of the most crucial aspects of any lab study is the ability to monitor variables in real-time. The Smart Laboratories have IoT-enabled devices which can send alerts the moment any variable goes out of the preset range, allowing for immediate corrective action. The monitoring relates to all aspects and devices in the lab.

The Tuttnauer T-Lab Eco product line features the T-Connect software, ensuring that all sterilization cycles are monitored and are accessible remotely, presenting information in real time, while storing all documentation in the cloud. What this means is that you can check the status of all your sterilization devices from any location outside of the lab.

Automated Data Collection

Gone are the days of manual notations. Smart laboratories use IoT-enabled devices like automated microscopes, autoclaves, smart pipettes, connected sensors that transmit data directly to centralized databases. This enhances accuracy and allows scientists to focus more on interpretative work rather than on data collection.

Interconnected Systems

One of the most significant advantages of a Smart Laboratory is system interconnectivity. Devices can either "talk" to each other; data from one can trigger actions in another, or the data from multiple devices can be reviewed and stored in one location.

The T-connect can connect to multiple devices, so that they can all be monitored and accessed in one central location. For example, the T-Lab Eco autoclave and the Tuttnauer Tiva washer can both be connected by T-Connect. All documentation and data are recorded and stored in the cloud, eliminating manual and paper intense work.

Smart Autoclaves

IoT-enabled autoclaves can be programmed to run sterilization cycles at specified times and alert technicians if there’s a malfunction, thereby maintaining an uninterrupted sterilization process. This is becoming an integral part of running and maintaining an advanced laboratory. Research centers and institutions will depend on sterilization devices like autoclaves to be connected and adapted to the Smart Laboratory. The T-Lab Eco autoclave, an autoclave designed for the use of research institutes, is ready to communicate with T-Connect software.

Energy Efficiency and Sustainability

Sustainability is another dimension where the Smart Laboratory excels. Energy consumption is optimized through smart lighting, climate control, and device operation schedules, contributing to lower operational costs and a reduced carbon footprint.

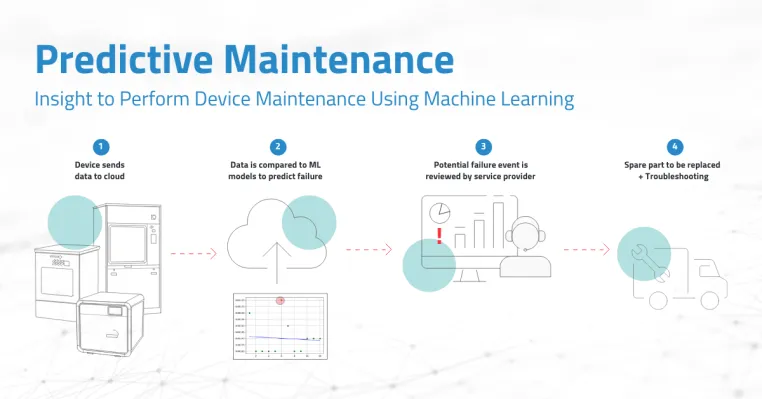

Predictive Maintenance

IoT can improve laboratories and research by significantly improving maintenance schedules. If any piece of equipment is down, it could produce inaccurate information, stop ongoing work and hinder research efficacy. Predictive maintenance is critical as it uses IoT sensors to predict when a machine needs maintenance and specifically where the technical error is and alerts users.

Repairs can be expensive and time-consuming, so predictive maintenance reduces these costs by alerting users to either maintain equipment before it breaks or specify what the repair is, so your service provider comes prepared and ready to fix the device first time around.

Leveraging the Tuttnauer T-Connect for your laboratory devices will enable a critical advantage of predictive maintenance. The software performs technical diagnostics that will advise where and what any technical errors are that occur. The fact that your service provider will already know the technical error before arriving is a gamechanger. Many of the errors can even be resolved remotely and those that cannot be dealt with remotely, can at least be resolved more efficiently, thus reducing your machine downtime.

A Holistic Approach

A Smart Laboratory takes a holistic approach to lab operations. From automating mundane tasks to enabling remote operations and integrating advanced sterilization techniques, it leverages IoT and other technologies to create a seamlessly interconnected, efficient, and compliant work environment.

The transformation towards Smart Laboratories is more than just a technological shift; it’s a paradigm change in how research and experiments are conducted. IoT is not merely an enabler but a catalyst that’s making laboratories smarter, more efficient, and increasingly reliable. The ongoing advancements promise an even more exciting future, where Smart Laboratories become the norm rather than the exception.