Consider these 7 important factors when evaluating instrument packaging in your dental practice.

Using incorrect packaging material

Using packaging material not designed for autoclave sterilization, such as regular plastic bags or aluminum foil, can lead to contamination of other instruments and the autoclave chamber.

Autoclaves use high heat and steam to sterilize all instruments within the chamber thoroughly. However, if wrapped in material not designed for autoclaving, the heat and steam may not penetrate properly and cause incomplete sterilization of the instruments.

Improper packaging can also damage instruments due to moisture getting trapped in the package or thermos-chemical reactions occurring, such as plastic degradation. This damage can lead to a shortened lifespan of instruments, resulting in more frequent replacements.

For instance, purchasing a quality pouch for your instruments can make a difference. Tuttnauer Tyvek Pouches and Reels meet the Medical Industry's requirement for high quality, hygiene and safety levels. Suitable for the packing of any Medical Device before sterilization and for maintaining the sterility after sterilization. Choose from a wide range of standard sizes and for double packing purposes.

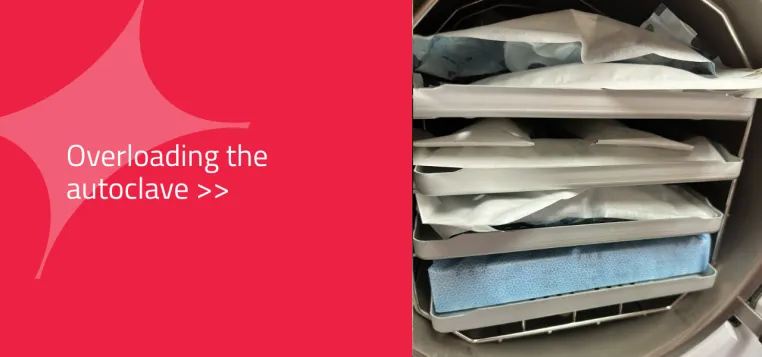

Overfilling packages

When packages are overfilled with items, large air-pockets could form, resulting in uneven distribution of pressure, preventing steam from reaching all contents of the package during the sterilization process. As a result, sterilization may fail, posing potential risks to patient safety.

Specifically, items enclosed in pouches should have sufficient space to lay flat or move freely within the package. For instance, dental scalers placed in sterilization pouches should be able to roll around or lay flat inside the pouch. If they cannot do so due to overfilling, opting for a larger pouch or dividing the instruments into multiple pouches is recommended.

By ensuring adequate spacing and proper arrangement within sterilization pouches, optimal steam penetration can be achieved, promoting effective sterilization of dental instruments. This proactive approach significantly reduces the likelihood of inadequate sterilization and enhances patient safety within the dental practice.

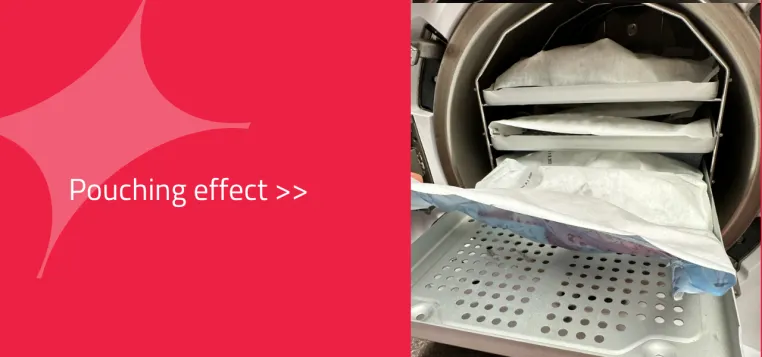

Wrapping packages incorrectly

Incorrectly wrapping packages can lead to inadequate steam penetration and incomplete sterilization. Packages should be wrapped securely but not too tightly to allow steam to penetrate. This means, if using pouches, seal on the perforated line, and if using wraps, know the best way to wrap the instruments according to the instructions for use.

A common mistake observed in sterilization is the over-folding of pouches, resulting in the plastic layers touching each other. It is crucial to emphasize the importance of folding only along the designated perforated line. Over-folding not only compromises the integrity of the pouch but also obstructs the adequate penetration and flow of steam through the material, thereby jeopardizing the sterilization of all instruments contained within.

Proper wrapping helps maximize efficiency when using an autoclave. The correct technique exposes all items while ensuring secure containment within their packaging material. This can also reduce time spent re-wrapping instruments and prevents additional water spots on surfaces due to over-saturation caused by improper wrapping techniques. Incorrect wrapping techniques could also result in decreased post-sterilization shelf-life of the contents in the wrapped package.

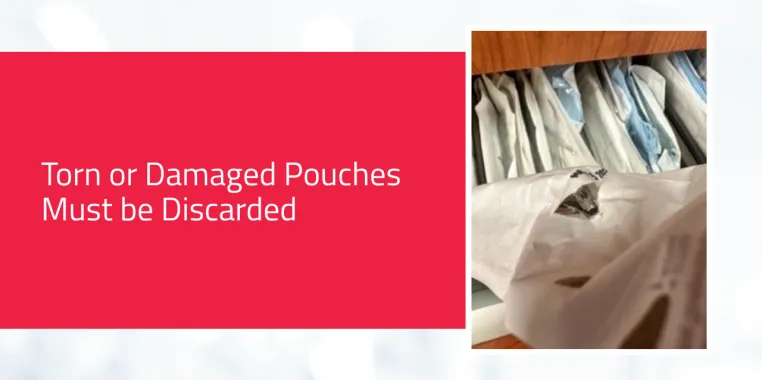

Using damaged packaging material

Damaged packaging material, such as torn or punctured wraps or damaged pouches, can lead to contamination of the instruments and put patients at risk of infection. Any tears or punctures in the packaging will allow for contamination once the items are removed from the autoclave. As a result, these packages must be checked for integrity before use to avoid compromising sterility.

The risk of mishaps during sterilization is heightened when dental professionals find themselves in a time crunch. Instances such as hurriedly placing instruments, like scalers, into pouches can result in the accidental piercing of the pouch material. Similarly, failing to ensure that all instruments are securely placed within a cassette before wrapping can lead to an instrument protruding from the package, posing a potential sharp injury to anyone handling the cassette. Furthermore, an instrument that extends beyond the package will not undergo proper sterilization and remain non-sterile even after autoclaving.

These scenarios underscore the importance of exercising caution and attentiveness during instrument handling and cassette preparation. The risk of piercing the pouch material or protruding instruments can be mitigated by carefully placing instruments within pouches and ensuring their complete containment within cassettes. These preventive measures not only safeguard the safety of dental professionals handling the cassettes but also guarantee the effectiveness of the sterilization process.

Not properly labeling packages

Properly labeling packages in an autoclave is essential for ensuring the sterility of medical instruments. Labeling packages with the date, load number of the day, initials of the person packaging, and sterilizer used provides an accurate record for tracing any potential problems related to sterilization. This helps ensure that all instruments are properly sterilized and allows professionals to identify any issues that may have occurred during the process.

Additionally, by including the initials of the packer on each package, any potential mistakes can be traced back quickly and easily, potentially identifying any gaps in staff education of proper autoclave use that require addressing.

In the event of a failed biological indicator validation, the labeling system enables dental professionals to swiftly locate and isolate any affected instruments. Adhering to established quarantine protocols can safely withhold these instruments from use until the issue is resolved and retesting confirms successful sterilization. This proactive approach helps maintain high patient safety and ensures that only thoroughly sterilized instruments are utilized during dental procedures. Always refer to the guidelines as well for your autoclave’s IFU on the steps that should be followed regarding B.I. test fails.

Failure to use chemical indicators

Chemical indicators are essential when using an autoclave because they can visually indicate that many necessary parameters have been met for proper sterilization.

Temperature-sensitive strips are widely employed as the most common type of indicator in sterilization processes, undergoing a color change once the required temperature is reached. However, having a temperature-responsive indicator on the outside of the package AND a comprehensive chemical indicator on the inside that accounts for multiple variables such as time, temperature, and pressure is crucial.

Placing a chemical indicator on the outside of the packaging provides a visual cue to indicate whether the package has undergone the necessary temperature threshold. This external indicator is essential for quick verification and serves as an initial assurance of successful sterilization.

Internally, a chemical indicator that responds to multiple variables, including time, temperature, and pressure, is indispensable. This indicator offers a more comprehensive and accurate assessment of the sterilization conditions within the packaging. By monitoring these critical variables, dental professionals can ascertain that the sterilization process has been properly conducted, ensuring the safety and integrity of the instruments contained within. Find out more about Tuttnauer chemical indicator options: https://tuttnauer.com/consumables/chemical-indicators/steam-indicators

Single-use is single-use

Do not reuse pouches or wraps for more than one sterilization cycle. Repeated exposure to high temperatures and steam can cause them to break down, increasing the risk of contamination.

Ensure the correct use of packaging to reduce the risk of cross-contamination, enhance infection control in your clinic, and keep everyone safe.

Always refer to the guidelines, as well as your instruments' & autoclave's IFUs pertaining to the proper sterilization procedures

*wraps / packaging are not currently offered in the U.S.