By implementing a systematic workflow, dental professionals can effectively manage the complex operations of the sterilization center. This entails defining streamlined processes for instrument reprocessing, setting up for the next patient, and ensuring seamless retrieval of items from sterile storage. Moreover, labeling various areas within the sterilization center enhances efficiency and minimizes the risk of errors or oversights. Clear and visible labels enable easy identification of different zones, tools, and consumables, ensuring that each component is utilized in the appropriate context, ultimately reducing the chances of cross-contamination and infection transmission.

Establishing a well-defined workflow and employing comprehensive labeling practices in the sterilization center is paramount. These measures optimize operational efficiency and mitigate the risk of infection control breaches, safeguarding dental healthcare professionals' and patients' well-being and safety.

So, what can creating workflows and mandating labeling in the steri-center do for your clinic?

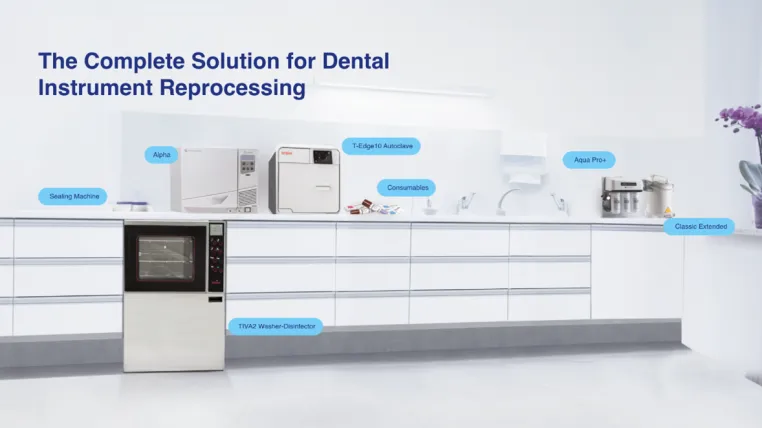

Tuttnauer offers a thermal printer option with the Tuttnauer autoclave devices, that is compatible with all machines, easy to use.

1. Ensure the safety of patients (and staff!)

Effective labeling of various areas and establishing workflows in the steri-center can help prevent the spread of infectious diseases. This helps patient safety outcomes by minimizing the risk that the tools used on one patient are not placed on the wrong side of the steri-center or sterile instruments are not placed on the side where dirty instruments are being received.

Cross-contamination is a leading cause of infection in dental practices, so it is essential to have a system in place to prevent it. Establishing a workflow with proper zones for dental offices might look like:

- Receiving dirty/contaminated instruments

- Cleaning/Rinsing/Drying

- Inspection and packaging

- Sterilization

- Storage of sterile items

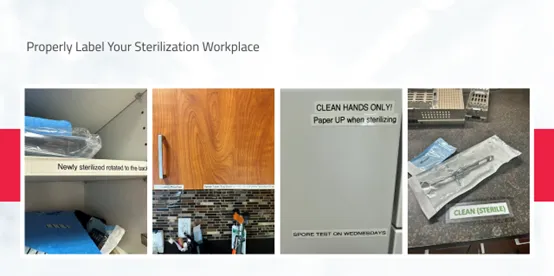

Placing labels to show team members that certain areas of the steri-center are dirty vs. clean is simple yet very effective at reducing the chances of cross-contamination. Implementing effective labeling and workflows in the steri-center is crucial for preventing the spread of infectious diseases, minimizing cross-contamination, and ensuring patient safety through proper sterilization and storage of instruments.

2. Improve efficiency

Implementing well-defined workflows and comprehensive labeling practices in the sterilization center enhances operational efficiency and contributes to the dental team's overall effectiveness. The presence of clear labels within the steri-center becomes particularly valuable for new team members, temporary staff, or individuals who are not extensively familiar with the intricacies of the sterilization process. Labels serve as visual cues, guiding personnel through the flow of operations and indicating the appropriate placement of instruments and supplies.

For instance, by labeling the outside of the autoclave with crucial details such as packaging instructions and whether the handles should be touched with clean or dirty hands, potential errors in sterilization practices and cross-contamination can be significantly reduced. The labels provide a simple yet effective reminder to follow the correct procedures, preventing mistakes and ensuring that each instrument undergoes proper sterilization.

By enabling easier comprehension of the workflow and facilitating adherence to established protocols, labeling in the steri-center promotes a cohesive and efficient team dynamic. It ensures that all team members, regardless of their familiarity with the sterilization process, can quickly grasp the essential steps and correctly handle instruments and supplies. Consequently, the implementation of labeling practices contributes to a higher level of teamwork and consistency in infection control measures, ultimately enhancing patient safety and the overall quality of care provided by the dental office.

3. Maintain compliance

Clear labeling within the steri-center serves as a visual aid for compliance. The labels can clearly display essential information, such as proper packaging techniques, designated storage areas, handling instructions, and the current steri-center workflow. This ensures that all team members have easy access to vital information and can readily follow the correct procedures, minimizing the risk of errors or non-compliance.

Moreover, established workflows help streamline operations within the sterilization center, ensuring that each step of the sterilization process is properly executed. A well-structured workflow acts as a roadmap, guiding dental healthcare professionals through the necessary tasks and ensuring that no crucial steps are missed. This level of consistency in processes promotes adherence to compliance requirements and helps maintain a high standard of infection control practices.

By incorporating proper labeling and established workflows, dental practices create an environment where staff members are empowered to consistently follow regulatory guidelines. This proactive approach to compliance protects patients' health and safety and safeguards the dental practice's reputation and integrity.

4. Reducing errors

Errors in instrument sterilization often go unseen. Proper labeling and workflow processes can help reduce mistakes in equipment processing, such as incorrect packaging, issues with the autoclave, mislabeling, or missing steps. In addition, instituting regular quality checks within the workflow can help identify potential errors before they become a problem.

Having a staff training program to train and troubleshoot the workflows can help ensure that employees are knowledgeable about utilizing the steri-center. This can help reduce the risk of errors and ensure that instruments are processed safely.

5. Facilitating communnication

Implementing workflows and effective labeling systems within the steri-center can greatly enhance communication among staff members and different departments, fostering a cohesive and collaborative environment focused on shared goals. By ensuring that everyone is on the same page, the risk of sterilization breaches can be significantly reduced. How often do we observe team members inadvertently placing instruments in areas that could lead to cross-contamination, handling equipment with unclean hands, or struggling to locate essential tools by rummaging through numerous drawers? Fortunately, there are more efficient and effective means of communication to convey protocols and ensure the proper organization of items within the steri-center.

By clearly defining and labeling specific areas, the steri-center becomes a hub of streamlined communication. Vital information, protocols, and designated locations can be visually communicated through labels, providing an intuitive and accessible framework for the entire team. This simple yet powerful approach minimizes confusion, increases efficiency, and promotes adherence to established guidelines, thereby reducing the likelihood of errors and improving overall patient safety.

In conclusion, implementing workflows and embracing effective labeling strategies within the steri-center not only streamlines operations but also unlocks the potential for improved communication among team members. This enhanced communication fosters a culture of collaboration, reduces the risk of sterilization breaches, and ensures that dental professionals can easily access the necessary tools and information to provide optimal care.