Running a subpar autoclave puts your practice at a higher risk of spreading infections, cross-infection, and contamination, let alone the inefficiencies that end up costing you time and money.

After working in the dental industry for so many years, I can tell you with confidence that one autoclave that is not subpar is the T-Edge from Tuttnauer, whose features make it an ideal choice for the busy medical professionals.

Connectivity is the new wave in infection control

The connectivity of the T-Edge Autoclave is one of its most valuable features, especially in today's technology-focused world. A connected autoclave allows medical professionals to easily monitor and manage the sterilization process, even remotely. They can see the autoclave cycle data in real-time and receive alerts when the cycle is complete or when there is an issue that needs attention. This is essentially the bottom-line benefit that’s worth the feature many times over.

In comparison, the majority of older autoclaves require a certain amount of physical monitoring to ensure that instruments are properly sterilized, which is not easy or convenient, particularly in busy practices. The connectivity of an autoclave, however, means medical professionals can check the autoclave's cycle data and make sure that it is working as expected, without having to physically visit the autoclave.

It then stores and archives data, making infection control record keeping a breeze and ensuring compliance with regulatory requirements EN13060, ISO 13485, and CE certifications. It's almost like outsourcing a part of your infection control process so that you can give more of your attention to your patients.

Connectivity options and innovations

Connectivity has introduced a host of options related to autoclaving. USB ports and data loggers have automated the process for information for logs, print-outs are available and information can be digitally archived. Best practices now include the use of electronic records by way of recording devices in sterilizers or an accessory device used for recordings and printouts. Options for labeling now also include barcoding with scans retained digitally. These are easily created, read and stored without the amount of effort required to manually create labeling. They also cannot be altered. Instrument tracking systems are also available that provide for traceability, and digital records are available for spore testing.

Tuttnauer autoclaves are designed with an advanced user-friendly control system for repeatable high performance. Including load tracing with barcodes. When loading the autoclave, a barcode reader can be used to scan the barcodes of each load. Once the cycle starts the barcode numbers will be printed together with cycle information.

The interface of the Tuttnauer Autoclaves is intuitive and user-friendly, which keeps it simple enough for medical professionals to quickly get up to speed with how to use it. This simplicity helps reduce training time and ensures that personnel can operate the autoclave with minimal user error. For dental professionals its use is compatible with commonly used software for easy data integration and streamlined reporting. The Tuttnauer T-Edge autoclave completes the entire sterilization process with the click of one button, providing ease of use and simplicity.

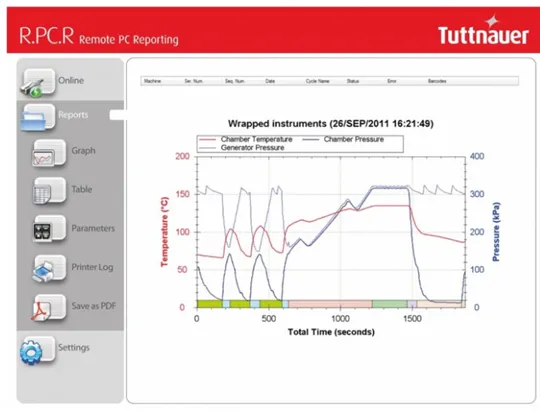

Since connectivity provides more options for documentation, the cycle data can be printed, transferred to a PC or network through the Ethernet connection, or the data can be stored in the autoclave. Remote PC Reporting (R.PC.R) Software automates and truly streamlines documentation, since all sterilization data can be saved as a pdf, transferred using a USB port or the ethernet or online, and with automated downloading of cycle information. It has become possible to digitally store information on the cycles performed, parameters reached, and to generate graphs, tables and charts for reports and analyses. It is also possible to remotely monitor multiple autoclaves, further streamlining efforts in a busy office.

.

Tuttnauer offers the optional addition of R.PC.R to be installed on the PC connected to the same network as the autoclave. The R.PC.R Software provides cycle records you can rely on and will provide the following service:

- Automatic recording of cycle information to any PC on your network via an Ethernet network

- Easily generate PDF reports

- No need to file printouts, saving you time

- Load Traceability - conveniently trace loads from a PC on your network with R.PC.R software. When barcodes of loads are scanned before a cycle starts, the barcode information is reported together with the cycle records. With R.PC.R you can see: Graphs of the cycle data, Numeric cycle data, Cycle print-outs, Measured values table, Parameter table.

With the modern technologically advanced autoclave, you'll have a reliable and efficient autoclave that can help you provide quality patient care.

Bringing innovative connectivity to sterilization devices

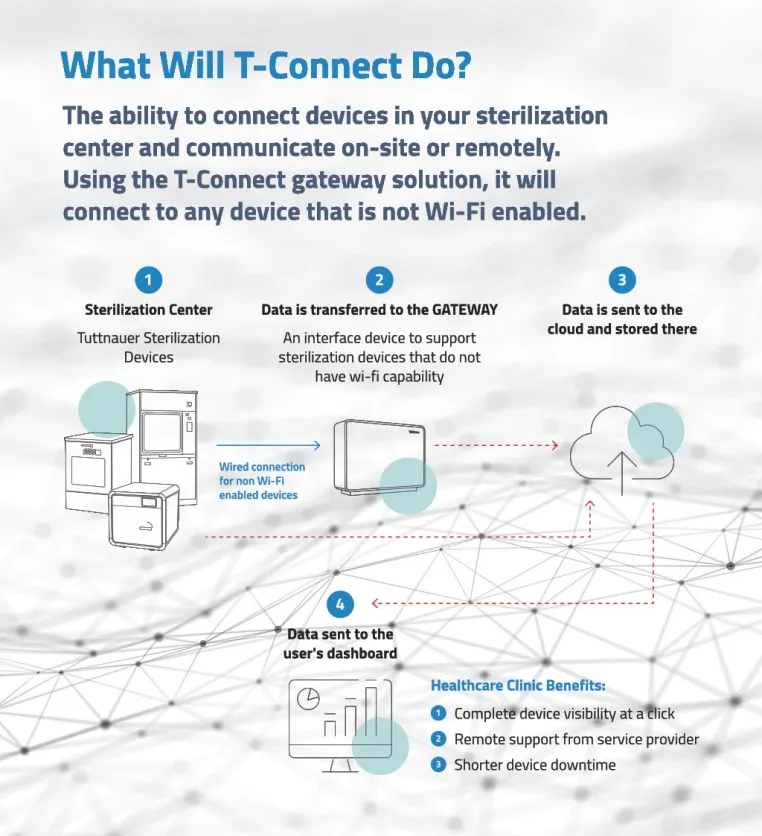

Tuttnauer has launched the T-Connect, a cloud based IoT solution for your sterilization center. It is based on a unique device connectivity, providing clinics with data intelligence in real time, accessible from anywhere, anytime, in a secure way. Essentially an intelligent solution designed for your improved success and business management. T-Connect will communicate with your sterilization devices onsite or remotely, providing a gateway solution for devices without wifi feature capability to connect and leverage the benefits of complete connectivity. T-Connect provides real time data documentation, analysis and troubleshooting. Knowing where and what the technical glitches are, allows you to have accelerated service, saving you time and money.

Why access to a quality autoclave is so important?

Access to a high-quality autoclave in any medical practice environment is essential because it ensures effective sterilization and disinfection of tools. The risks of running an autoclave that underperforms include the potential for cross-contamination or infection of patients or staff and increased costs associated with needing to replace tools more frequently than necessary.

The incidence of disease transmission from autoclaves in the dental industry is frustratingly more frequent than in other healthcare settings, so autoclaves must meet the highest standards.

While still in use in some practices, older models require frequent calibration and manual monitoring, which can be highly time-consuming. Advances in technology, however, have led to the development of autoclaves that are much easier to use and maintain.

Modern autoclaves have in-depth safety protocols and automated features, including cycle verification and monitoring. These models also come with advanced programming options that make it easy to customize sterilization cycles according to the type of tools being sterilized, which is a real game changer once you get used to it.

Features of the T-Edge autoclave

Designed with a patented closed-door drying system, the T-edge ensures fast and efficient drying. Considering how quickly we sometimes have to turn over patients, this speediness is a godsend for a high-volume practice. The 27-liter chamber means it can also sterilize larger instruments such as instruments used in implant treatments and oral and maxillofacial surgeries.

The autoclave also comes with an advanced LCD screen that allows monitoring of every stage of the sterilization process, and its safety features ensure that it will not overheat or under-oxygenate during the sterilization process.

To up your infection control game and protect your patients, staff and your business, you must invest in the best sterilization products out there, and there is nothing better than the T-Edge autoclave.

Watch this T-Edge video to learn more