The Function of the Autoclave Jacket

Did you know that most large autoclaves, like horizontal autoclaves, wear a jacket? Why? One of our upcoming posts in the series focuses on the autoclave jacket, which will reveal why we dress up the autoclave. For now it is important to understand the function of the jacket because it helps us understand how steam from the steam generator reaches the chamber. Steam supplied from the generator heats the autoclave jacket and circulates inside the jacket readily available for instant use. In a CSSD (Central Sterile Supply Department) or SPD (Sterile Processing Department) autoclave that sterilizes medical instruments, the autoclave jacket surrounds the chamber thereby heating the chamber, and in some configurations the jacket functions as the autoclave chamber steam source. A valve located between the jacket and the chamber opens letting steam from the jacket enter the chamber, which is then used for sterilization.

There are, however, exceptions. Steam supply from the jacket is applicable to hospital autoclaves, such as those found in the CSSD (also called the SPD). In the case of some autoclaves different steam types are used for different purposes. "Dirty" steam is used to heat up the jacket and is used from either the steam generator or the building's steam. Dirty refers to the quality of steam that is produced. Obviously it is not dirty, it just means that the quality of steam produced is not the highest quality, which is fine in many cases such as instrument sterilization in hospitals or the medical industry. Clean or "pure" steam that comes in contact with materials that require sterilization is generated without coming into contact with any heating elements that can reduce the quality of steam.

What is Clean Steam?

Conventional steam, also known as dirty steam, contains foreign particles from chemicals, from the metal and from the feed water. Normally this does not cause any problems and can be used in many applications such as in hospitals when sterilizing medical instruments. But even though the steam temperatures and humidity are according to requirements for killing most germs, conventional or “dirty steam” cannot be considered 100% clean.

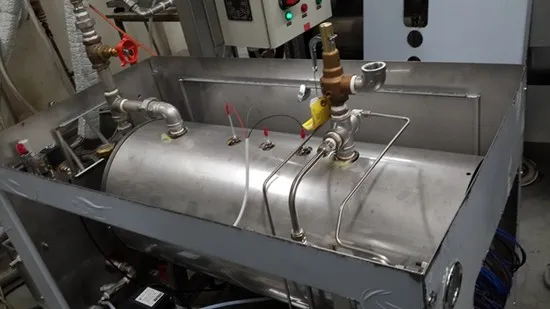

Clean steam is commonly used in high containment BSL3 (biosafety level 3) laboratories that require a higher quality of steam. High quality steam is needed for tissue culture work, sterile water preparation and other special processes. Building steam is not suffiecient to produce clean steam. Clean steam will be produced by a steam generator that uses pipes and fittings that are constructed from stainless steel and brass and pneumatically operated valves, which reduce maintenance and downtime. Stainless steel piping, fittings, and components are made of a higher grade of stainless steel called 316L.

The highest grade of pure/clean steam is generated by a steam to steam generator. The steam is produced by using either the buiding steam or steam from a steam generator. The steam produced does not come into contact with heating elements. Typical uses for this type of clean steam include pharmaceutical applications and food processing

Which Steam Generator Suites Your Autoclave?

Let’s zoom in and examine the different steam supply solutions available. We will understand why and when each solution is used. Ideally, it is preferred to supply steam to the autoclave from a dedicated built-in or stand-alone steam generator, which is designed and constructed for the sole purpose of steam supply for autoclave sterilization. A dedicated steam generator , whether built-in or stand alone is designed with an optimal operating pressure, quality piping and components to ensure that the process of sterilization by steam is not compromised.

Is your Autoclave Steam Generator Introverted or Extroverted?

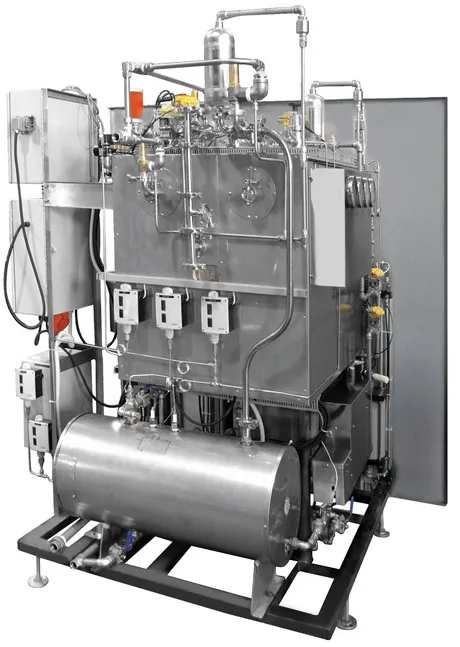

Autoclaves don't have personalities, but the autoclave steam generator can be positioned either under the autoclave, this is called a built-in steam generator, or it can be external to the autoclave, an independent standalone steam generator.

The main consideration when deciding between a built-in or a standalone steam generator is the size of the autoclave, whether it’s a single or double door autoclave and the steam generator's size. Every CSSD prefers a built-in steam generator with the obvious space saving advantages. Sometimes the autoclave is just too large and then there's no other option but to position it by the side of the autoclave and there were even cases when the steam generator was on top of the autoclave.

Dual Steam Supply for Your Autoclave - Why Not Enjoy Both Worlds?

If you want to enjoy both worlds Tuttnauer supplies a hybrid steam supply solution - the dual steam supply autoclave. An autoclave with a dual steam supply has two steam lines connected to the autoclave: One line supplies steam from the building’s steam network and the second line supplies steam from a dedicated steam generator. The main reason for selecting an autoclave with a dual steam supply is in cases when building steam supply is irregular and affected by unstable environmental conditions. Another reason to choose an autoclave with a dual steam supply is that there are times when the availability of steam is turned off. Hospitals sometimes turn off the steam supply in the evenings and nights and often the autoclave needs to function 24/7 to keep up with high instrument turnaround. This is when the dedicated steam generator will kick inn. If the autoclave needs to be ready and functioning at all hours, then having a dual steam supply is important.

Steam to Steam

An alternative way to generate steam is the steam to steam generator, which is also called a clean steam generator. As discussed, this steam is used usually only in advanced laboratories or pharmaceutical autoclaves. It is needed in cases that the level of sterilization requires the steam to be pure when the quality of building steam or standard steam generator is not high enough. It uses plant steam which is called “dirty” steam to generate pure steam. The steam that enters the chamber was produced from water that did not come into contact with heating elements. The water turned into steam by steam and therefore the water doesn't come into contact with electrical parts.

Clean steam uses the energy of the "black" steam for generating steam, instead of using electricity to generate steam. This saves a connection to a high current steam generator by using the building steam to generate the clean steam.

Conclusion

We hope you are now familiar with how steam works, its quality and the different options of autoclave steam generators and steam supply. After we've raised the pressure of the autoclave with steam, we will dramatically reduce it and see how vacuum works in an autoclave and why it is needed. We will explain the ins and outs of the vacuum. What is deep vacuum? Why do we pulse? Why is getting rid of the air important for sterilization assurance? and more. Stay tuned.

But before we take the pressure down, we want to hear from you. How is steam supplied to your autoclave? Did you ever encounter any difficulties or challenges with steam supply? Let us know and if you have questions, we can provide some good answers.